The vent’s housing is made of powder painted steel plate. The engine, with an outer rotor, is placed inside the housing and fixed with M4 screws. The vent’s metal rotor is fixed directly on the engine’s outer rotor. The vent’s sucking flange is secured with a shield, preventing anything from touching the moving parts (the turbine). The vent can be equipped with a flap on the intake for efficiency adjustment or a flap on the exhaust for natural thrust adjustment. The vent’s engine is tailored for voltage spinning speed adjustment. The fan has a CE declaration of conformity.

RV-12 type fans in various makes are tailored for blowing the air in C.H. boilers and other technological devices, at a temperature from -15C up to +40C and relative humidity up to 90%. The fan is not intended for use as a standalone home appliance.

Main application: coal furnaces and retort feeder furnaces 25 – 50 kW.

Specification

| Drive engine type: | inductive with a work condenser, outer rotor |

| Voltage rating: | 230 V |

| Frequency rating: | 50 Hz |

| Power input: | 70 W |

| Rated current: | 0,35 A |

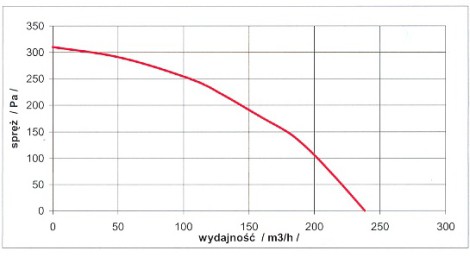

| Max. efficiency: | 240 m3/h |

| Max. concentration: | 310 Pa |

| Spins at max. efficiency: | 2450 obr/min |

| Spins at max. concentration: |

2850 obr/min

|

| Work type: | S1 |

| Work placement: | any |

| Protection level: | IP 20 |

| Main isolation: | Class B |

| Protection from abnormal use: | engine’s thermal safety pad |

| Acoustic power level: | <60 dB(A) |

| Weight: | 2,0 kg |

| Minimum voltage rating: | 80 V |

Fan specification

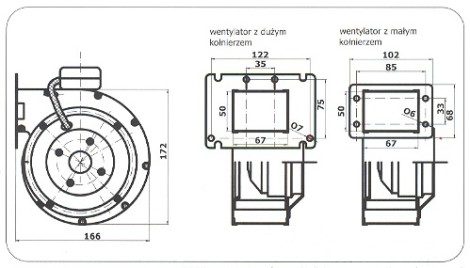

Overall dimension diagram